Let’s execute

“The offshore wind sector is entering a new phase requiring a massive manufacturing and installation scale-up. Building a subsidy-free offshore wind farm should not mean that the companies involved make losses. We have to be economically sustainable as an industry. Therefore, it is vital to innovate to reduce costs further.” Says Jan van der Tempel, Chairman of GROW. “Mind you, we have to build 1000 turbines annually to drive the global energy transition. To make this happen, we must speed up all processes and align the complete supply chain.”

Furthermore, the energy transition is not done by building offshore wind alone. We also have to tackle how we will deliver this massive capacity to the onshore energy demand and contribute to a reliable energy system. Conversion into hydrogen will be one of the technological solutions. Now, this electrolysis route is too expensive. One way to reduce the cost is to bring down the cost of offshore wind, which is 60% of the total cost of hydrogen production. The rest, 40%, is needed for the conversion to hydrogen.

Jan van der Tempel is an inventor in heart and soul and a big fan of offshore wind. He is CEO of Ampelmann and DOT and is involved in several innovation platforms under the Energy Innovation NL. And: chairman of the GROW Foundation.

|

|

Bigger versus more?

|

|

Government: listen to the industry

Jan van der Tempel: “Policymakers should not only put impressive targets in their policy documents, but they should equally follow up with deployment and innovation policies that make it happen. They should work together with the industry. We already are a very mature industry. We see where markets are going and what innovations could be viable in these markets.

In the past decades, we have seen governments doing it ‘wrong’ and doing it ‘right’. And now, we have found the golden mix that is so successful but also creates new challenges. We have to work across sectoral and national borders in coordination with the industry.”

|

|

Let's fully utilise the innovation support schemes

“Let’s acknowledge that the innovation subsidies in the Netherlands are fantastic!” says Jan van der Tempel. “Yet, the available innovation budgets have not been fully utilised the last couple of years.

Typically, a beautifully sounding immature idea easily acquires an innovation subsidy. It gets nasty in that centrepiece where we have to scale up and show that it works at scale. That requires a lot of money and cooperation. Many people put their time and money into that innovation. Then the government kills it because – in their opinion – it does not align with the subsidy scheme, European rules or their assessment of the viability of the innovation. The industry has to write proper and probably better proposals. But the government can show more trust in the opinion and commitment of the industry partners to such an innovation. Clearly, support for innovation projects needs to meet the legal and regulatory conditions, but there is room for that. In the past years, we did not get to spend the annual 50 million euro budget in the Dutch renewable energy innovation scheme (HER+): I think as a country we do not do ourselves a big favour.”

Ampelmann: expertise in motion compensated gangway systems.

Deltares: expertise in geotechnical research

DNV: expertise in certification

DOT: expertise in wind turbines

Eneco: expertise in project development and operating wind farms

Royal IHC: expertise in installation equipment

LM Wind Power: expertise in wind turbines

MARIN: expertise in hydrodynamics

Innovation takes time

Jan is the mastermind behind the slip joint technology, which took 20 years to get to the market. “We need to speed up this innovation process, as climate change will not give us another 20 years.” Innovations do take time. But the recipe for increasing the pace is not too complicated: Go step-by-step. Allow start-ups to have new ideas and out-of-the-box thinking. Use some money on radical ideas and still invest in more mature innovations. Try it out, and test them. In 2030 we have only just begun with the deployment of offshore wind. Be aware that innovating takes time. What we invest now may go to market in or after 2030. But the sooner, the better. Let’s execute.

|

|

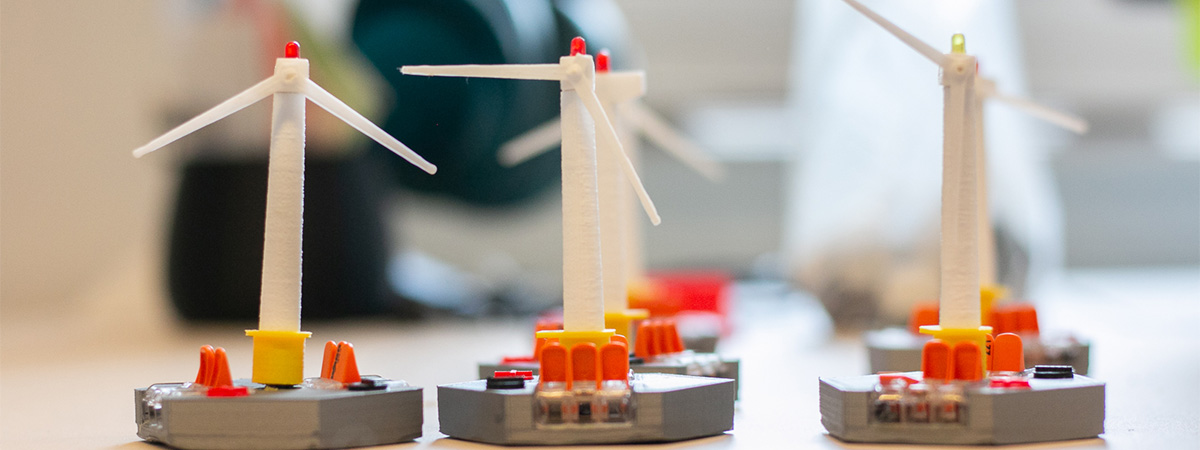

We need people

Reaching the deployment targets requires many more people that work in the offshore wind sector, both brains and hands. Innovation can result in manufacturing and installation processes that require fewer people. However, we definitely need well-trained people, such as technicians and project managers. How can we accomplish that? Go to primary schools, and let students and professionals play with the water table. Teach young kids about technology. This is critical for societal support and for harvesting the new talent that society needs. We have to get them inspired.

TNO: expertise in applied research on novel measurement techniques

TU Delft: expertise in geotechnical modelling

Van Oord: expertise in installation

Vattenfall: Design and maintenance of offshore windfarm

The Dutch way

Within GROW, we can accomplish things that individual partners cannot accomplish alone. Because we work in the Dutch way: we invest in trust, are straightforward, open in communication and how we work together and co-operate with competitors to serve the industry as a whole. And: act on it.

© GROW ’26