Solid as a rock

The Tubular Pile Pull-out Testing (TPPT) project impressively manages to mimic the conditions at sea for open tubular piles used for the mooring of floating wind turbines. Jan Kenkhuis explains: “Can we use open tubular piles for anchoring large floating wind turbines to keep the floating wind turbines on location in a harsh environment? That’s what we are testing here. We are actually simulating at this moment a storm condition. A serious storm, because that’s what we design for. Calm weather days are not really a concern.”

And then we thought, wow….

Have a look at Jan's profile on LinkedIn

|

|

Deep waters, floating wind turbines

Therefore, tests are necessary to prove the soil strength parameters and show a lower effect of cyclic degradation, which can improve the design factors for the static and cyclic pull-out loads.

|

|

Test, assemble, analyse, interpret… and improve.

Have a look at Jeroen's profile on LinkedIn

|

|

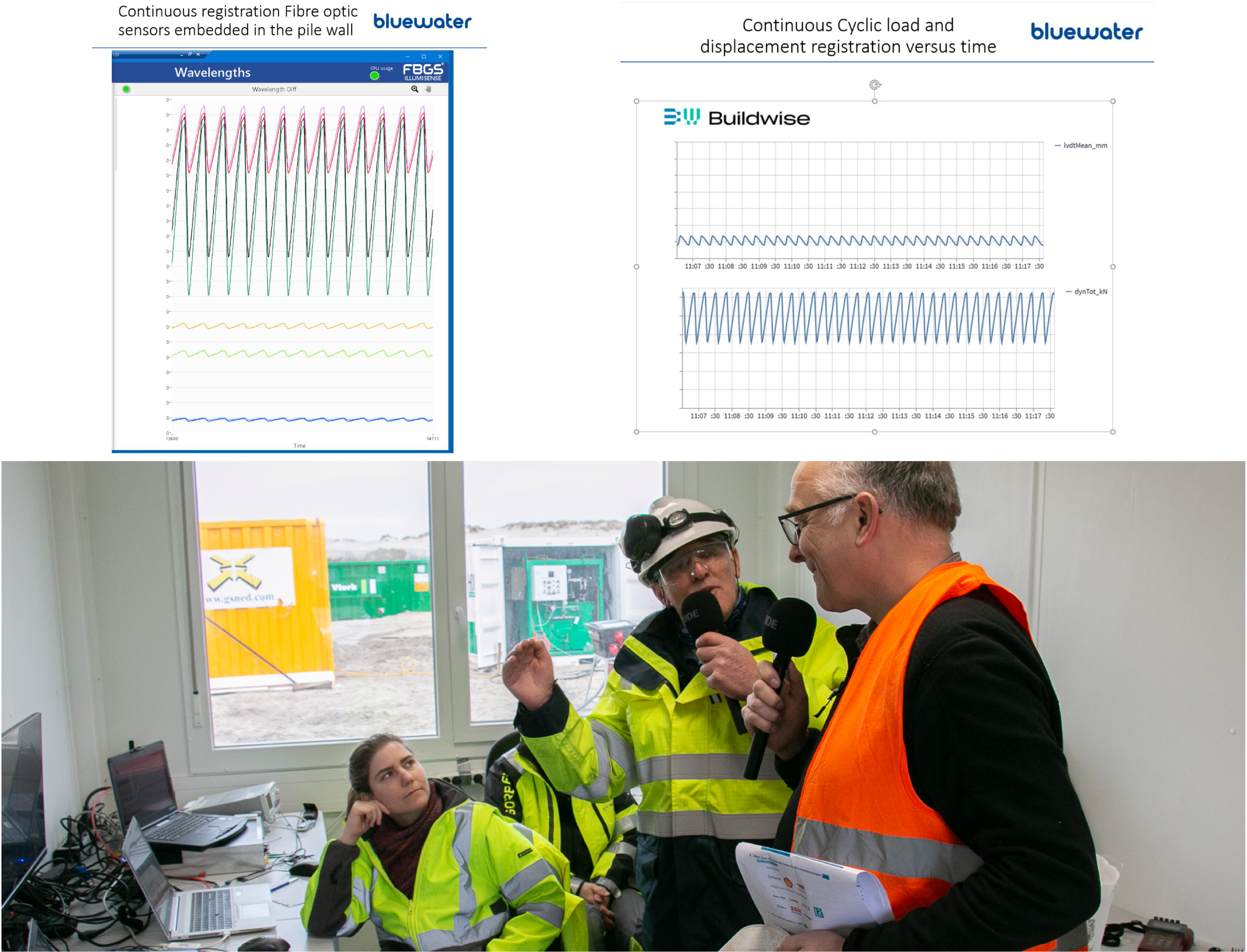

Collecting measurement results and correlating them with the loads induced at the top of the pile is crucial information to reinforce the design practices for offshore renewable foundations. These tests will be helpful for the design of future anchor points for floating offshore wind by providing a better understanding of the level of degradation of the soil-pile interface under cyclic tensile loads.

|

|

“Like the soil profiles at sea, the research project consists of many layers. Jan says, “First, we perform the test with the piles and collect as much information as possible. And then, a lot of research, analysis, and interpretation work will be done to see how these test results can improve the design, rules, and regulations for designing anchor piles.”

The yellow test structure at the Maasvlakte might seem static, but it is not. Jan: “Actually, at the moment, we are applying a cyclic load on the pile, which is between 300 and 600 tonnes. And we register all the pile movements and the loads we use.” What we want to understand is the effects that the impact of the forces will have on the anchor point. Will the soil get stiffer or softer? If it softens, the anchor pile could come free. That’s what the team wants to simulate and measure in order to prevent this from happening in reality.

|

|

First results

The test results are already looking promising. Several computer screens depict the incoming data. The screens show the applied loads and the displacement of the open tubular pile in the soil.

|

|

Safety first

The design of the anchor point needs to guarantee proper functioning for over 30 years. “Currently, investors don’t feel comfortable enough unless high safety margins are used for the design. By being able to improve the design and the uncertainties there, we could be saving a significant amount of steel per foundation.

The Netherlands: Waterland

Interestingly, the Dutch government is funding the research, although floating wind will probably not be used in the Dutch shallow waters of the North Sea. Then why subsidise it? In deeper waters, it will be the dominant future technique. “The rest of the world,” Jeroen emphasises, “wants to learn more about the pile behaviour in the soil to optimise the pile foundation design.” Who better to learn from than people in The Netherlands? “We are used to working with sand and water,” Jeroen explains. “And through the TU Delft and several companies, there is much expertise and employment of people in the Netherlands related to renewable energy in general and offshore wind in particular. It will be an excellent export product for the Dutch industry.”

Bluewater: expertise in offshore mooring systems

Deltares: expertise in geotechnical research

DEME: expertise in dredging and offshore installations

Jera: expertise in project development and operating wind farms

Lloyd's Register: expertise in certification of offshore systems

Port of Rotterdam: expertise in harbour design and operations

SBM Offshore: expertise in offshore mooring systems

Shell: expertise in project development and operating wind farms

Sofec: expertise in offshore mooring systems

Total Energies: expertise in project development and operating wind farms

Find out more about the TPPT project

|

|

© GROW ’26