The Sound of Silence

To receive an update on the SIMOX project, David de Jager visited the specially prepared SIMOX demonstration site at the Port of Amsterdam to meet two key people involved in the project: Ahmed Elkadi and Mark Post, both from Deltares. Here, researchers and industry partners are at that time installing and testing monopiles side by side, using several innovative installation techniques.

|

|

In September 2022, the edition titled "Getting to the Bottom of Things" featured Ahmed and Mark, who provided insight into the need for new installation techniques and the initial small-scale tests conducted at the Water Soil Flume at Deltares. Those laboratory tests involved monopiles with diameters of only 0.3 meters. In 2024, the work was moved out of the lab and into full-scale field trials. The piles being tested at the SIMOX demonstration site are significantly larger, measuring 2.2 meters in diameter and 13.4 meters in length. While still smaller than full offshore monopiles (which may reach 15 meters in diameter in the future), these piles provide critical data at a larger scale than can be achieved in the lab.

|

|

“We’ve designed the test setup to be flexible and efficient,” explains Mark Post. “By loading two piles against each other, we can simulate offshore conditions in a controlled way, while keeping the testing process highly productive.”

|

|

Precision starts with the soil

A towering yellow steel structure, called the piling template, holds each pile perfectly vertical during installation. Offshore, this job is typically done by grippers mounted on vessels. On land, the custom-made template keeps piles stable as they are installed using various techniques.

"The template may look simple, but quite some thought went into designing it to ensure precise vertical installation," says Ahmed Elkadi.

The project partners provide much of the equipment used at the site and will be reused for future projects or research after the SIMOX tests are complete.

Have a look at Ahmed's profile on LinkedIn

|

|

How lateral load tests simulate offshore conditions

Once installed, the piles are subjected to lateral load tests to simulate the forces of wind and waves that turbines experience offshore. Using a large hydraulic jack — now hidden beneath a blue screen — forces of up to 6,000 kilonewtons are applied to the piles.

|

|

Both monotonic and cyclic tests are conducted, representing continuous and repeated offshore loading. The setup enables researchers to quickly switch between tests, thanks to a portable and efficient test frame developed by TU Delft.

Measuring every detail: sensors at work

The piles are equipped with sensors to capture detailed data throughout the installation and testing process. Acceleration sensors record vibrations caused by the installation tools, while strain gauges measure the deformation of the piles under load. Some piles are even equipped with soil sensors to measure stresses between the pile and the surrounding ground during driving.

"All this sensor data is essential input for calibrating our models. It allows us to predict better how piles behave during installation and under operational loads offshore," says Mark Post.

|

|

Nature’s unexpected role: toads and timing

With help from environmental specialists, a system of fences and buckets was installed to relocate the toads safely. What was expected to delay the project by a few days turned into a two-month wait. Eventually, testing could begin.

“It’s one of those unforeseen aspects you encounter when working in the field,” Ahmed reflects. “We’re fortunate that the port and specialists helped us resolve it carefully and responsibly.”

|

|

Managing vibrations — for people and machines

Although the test site is located in an industrial area, nearby warehouses contain sensitive robotic equipment. When test site preparation began, some vibrations were felt by neighbours. The team installed vibration monitoring on neighbouring buildings to ensure safety. Real-time measurements confirmed that vibrations stayed well within predicted and acceptable limits throughout the project.

"We had close contact with our neighbours from the very beginning," Mark says. "By installing monitoring and sharing data, we could demonstrate that our activities remained well within safe levels."

|

|

Measuring noise levels: in the air and underwater

Noise is a key concern for offshore wind installations. During testing, TU Delft monitors airborne noise levels on-site. While different from underwater noise that affects marine life, the measurements allow comparisons between techniques.

Vibratory installation methods prove to be much quieter than impact hammering. Standing close to the vibro-hammer requires no ear protection, unlike the impact hammer, where hearing protection is mandatory.

“This noise reduction not only benefits people but also has great potential for reducing underwater noise impacts on marine life,” emphasises Ahmed Elkadi. “Further research involving marine biologists and environmental agencies is still necessary to fully assess the impact of these new techniques on underwater ecosystems and future permitting requirements.”

|

|

A genuine team effort: collaboration in action

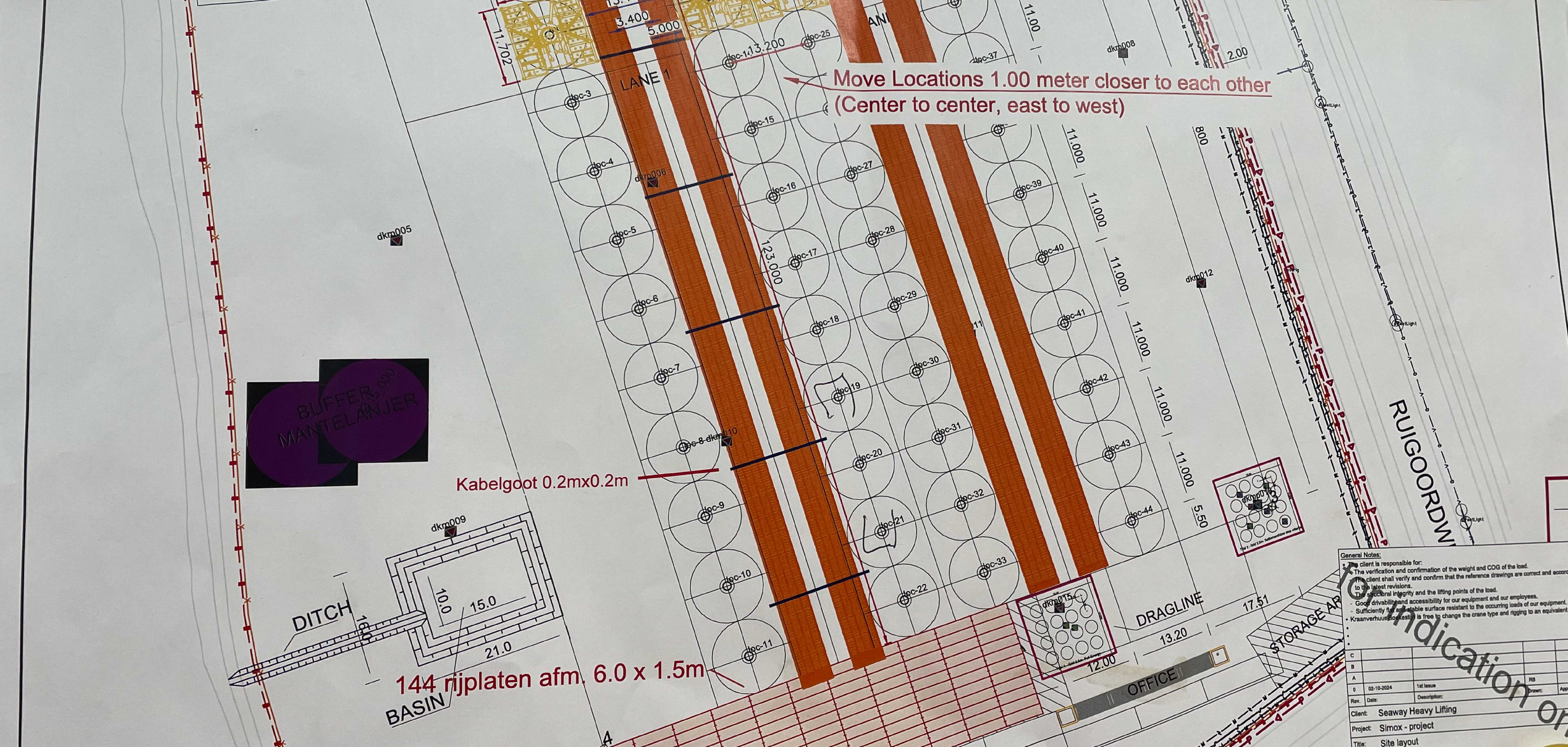

SIMOX is a great example of cooperation in offshore wind innovation. About the test site, the following organisations played a role:

- Boskalis and Cofra handled site preparation and soil compaction.

- Seaway7 oversaw lifting operations and site safety.

- DOT prepared the sensing and transport of the piles.

- TU Delft and Deltares led the scientific design and data collection.

- IQIP, CAPE Holland, GBM Works, and others provided installation expertise and equipment.

The experimental design required careful coordination. Mark Post explains how every detail, from pile dimensions to sensor placement, was planned.

“The daily coordination and careful preparation really paid off,” Mark says. “Despite the challenges, we are exactly on schedule.”

Boskalis: expertise in installation

Cape Holland: expertise in installation equipment

Deltares: expertise in geotechnical research

DOT: expertise in wind turbines

GBM Works: expertise in installation equipment

Heerema Marine Contractors and Heerema Engineering Solutions: expertise in installation

IQIP: Expertise in installation equipment

Ocean Winds: Expertise in project development and operating wind farms

Ørsted: expertise in project development and operating wind farms

|

|

Preparing for much larger piles

The test piles at the test site are still small compared to what is already being installed offshore. Monopiles now range in diameter from 10 to 15 meters and in length from up to 100 meters.

As turbines get larger, full-scale testing becomes increasingly important. Both Ahmed and Mark see great value in developing a permanent or semi-permanent full-scale test site in the Netherlands.

"With such a test site, we could accelerate innovation while reducing costs and permitting complexity," Ahmed explains. "If we want to meet the targets for offshore wind, we need to scale up, and we need to do it fast."

RWE: expertise in project development and operating wind farms

Seaway 7: expertise in installation

Shell: expertise in project development and operating wind farms

Siemens Gamesa: Expertise in wind turbines

Sif: expertise in monopiles

TNO: expertise in applied research on novel measurement techniques

|

|

Ready for the next step

With field testing now nearly complete, analysis of the collected data will begin. These results will help improve models, guide future installations, and inform environmental regulations and policies.

“You can only test such innovations when you really go to a larger scale,” concludes Ahmed Elkadi.

Thanks to SIMOX, the offshore wind sector moves one step closer to faster, quieter, and more sustainable installations.

Do you want to get an impression of the onshore tests for silent offshore wind installation technologies? Have a look at the short movie we made.

TKI Offshore Energy and the Netherlands Enterprise Agency support the SIMOX research project.

TotalEnergies: expertise in project development and operating wind farms

TU Delft: expertise in structural (dynamics) research

Van Oord: expertise in installation

Vattenfall: Design and maintenance of an offshore wind farm

Find out more about the SIMOX.

© GROW ’25